I’ve watched more than one Greenville restaurant owner freeze (yeah, pun intended) when an inspector walks over to the ice machine, pops the lid, and frowns. That “clean little cube” is treated as food under the South Carolina rules, and when that bin is slimy or the drop zone is dirty, it’s an easy way to lose your A and get more follow-ups than you’d like.

In this guide, I’ll walk you through how inspectors look at your ice, what really grows in that bin in our humid Upstate climate, and how to set up a cleaning routine that actually works in a busy kitchen. I’ll also explain where professional maintenance (like what we do at Appliance GrandMasters) quietly protects your grade and your sanity without turning this into a sales pitch.

From the inspector’s point of view, your ice bin is a shortcut to understanding your whole operation.

If the ice machine is dirty, they immediately wonder what the rest of the back-of-house looks like when nobody’s watching. That’s why “ice machine not clean to sight or touch” shows up so often in inspection reports.

A few important things to remember:

Ice is food.

That sounds obvious, but it’s easy to forget. Under the food code, ice is a ready-to-eat product. Anything that touches it—the bin, the baffle, the drop zone, the scoop—is treated just like a cutting board or prep table. If inspectors see slime, scale, or flakes inside, they’re required to call it out.

Food-contact surfaces have to be clean and sanitized.

It’s not enough for the outer shell of the machine to look nice. Inspectors check inside the bin, the underside of the lid, the drop zone, and sometimes the scoop storage. If those aren’t clean to sight and touch, it goes straight into your score.

Patterns matter.

If your last report already flagged the ice machine, a repeat violation can trigger a lower grade or a quicker re-inspection. That’s why it’s so important to fix the root problem, not just wipe things down the day before you expect a visit.

Bottom line: that quiet white box in the corner carries more weight than most people think.

Let’s talk about what’s really growing inside neglected ice machines, especially in our climate.

In the Upstate, ice machines fight three main enemies: biofilm, mold, and mineral scale, all boosted by heat and humidity.

Biofilm is that pink, orange, or black slime you see on plastic and metal surfaces. It’s a sticky mix of bacteria and organic residue that loves cool, damp, low-light spaces like your bin walls, drain lines, and drop zones. Once it takes hold, it doesn’t just stay in one spot. It spreads.

Mold shows up as dark spots or fuzzy growth on plastic and silicone. If you can see it on baffles, gaskets, or the underside of the lid, that’s a clear signal the machine has gone too long without a proper cleaning.

Mineral scale is the chalky white or off-white buildup on metal surfaces. It doesn’t look as “gross” as slime, but it insulates the evaporator, reduces ice production, and makes it harder to sanitize the machine properly.

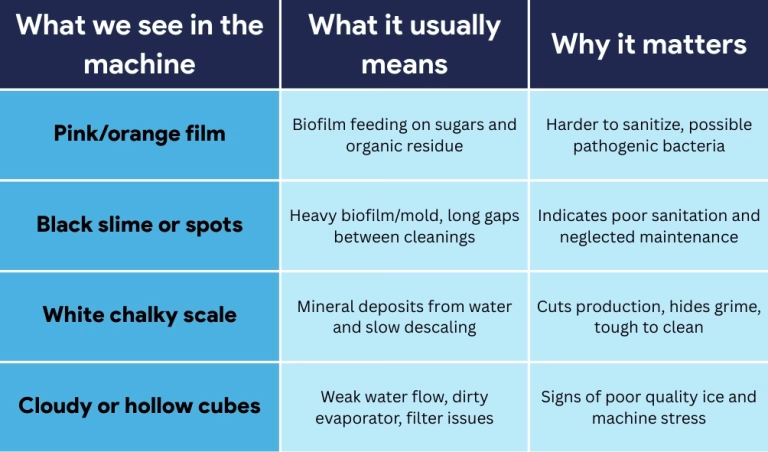

Here’s a quick snapshot of what we usually find in ice machines around Greenville:

You don’t need to memorize the microbiology. Just know this: if you can see film, spots, or scale, your inspector will see them too.

Most manufacturers recommend a full clean and sanitize every 3–6 months, sometimes more often in hot, humid, high-volume locations. Greenville checks all the “hard mode” boxes:

In real life, here’s what tends to work well for restaurants in Greenville and nearby areas:

High-volume bars and coffee shops usually do best with a full tear-down cleaning and sanitizing every 60–90 days. They’re scooping all day, doors and lids are constantly open, and sugar from drinks feeds biofilm fast.

Standard sit-down restaurants often land in the 90–120 day range for professional deep cleaning, backed up by weekly wipe-downs and consistent scoop sanitation from staff.

Seasonal or low-volume operations should still aim for at least every six months, plus a full clean before and after busy season.

If you’ve ever been written up for your ice machine, I’d lean toward cleaning more frequently. It’s cheaper and easier to maintain a clean machine than it is to recover from a really nasty one.

A lot of teams either over-touch the machine (and risk breaking something) or are so nervous they never touch it at all. There’s a solid middle ground.

Staff shouldn’t be tearing the machine apart or handling chemicals they’re not trained on. But they can keep the day-to-day surfaces under control with a simple routine.

Checks that nothing is sitting on or blocking the top of the machine

Anything deeper—panels off, descaling, working around wiring—that’s where I recommend bringing in a tech. It’s not just about protecting equipment; it’s about keeping your staff safe and avoiding downtime if something gets damaged in the process.

After working on these machines and reading a lot of inspection notes, the same mistakes show up again and again.

The first one is “out of sight, out of mind.” From the outside, the machine looks okay, but the underside of the lid, interior baffles, and hard-to-reach corners are covered in slime. Inspectors look in those spots on purpose.

The second is a clogged or slow drain. Meltwater that should be moving away from the ice sits in the bottom of the bin. That dirty water hits new cubes and gives your ice that gray, cloudy, or “off” look inspectors love to call out.

The third is the gap between what’s written and what’s real. There’s a cleaning schedule taped to the wall, but nobody actually follows it. When an inspector asks, “How often is this cleaned?” the answer is either silence or a guess.

The fourth is no documentation. Even if you do have a service company cleaning the machine, there are no records handy. A simple log or a folder with recent work orders goes a long way when someone is standing there with a clipboard.

None of this comes from bad intentions. It’s just busy kitchens, limited time, and no clear owner for the ice machine. That’s fixable.

This is where the “we repair and maintain this stuff” side of my job comes in. At Appliance GrandMasters, we see ice machines not just when they’re installed, but after they’ve been hammered by a Greenville summer rush.

When a restaurant brings us in for ongoing ice machine maintenance, we usually build the plan around three simple ideas.

We break the machine down the way it’s meant to be serviced, not just wiped. That means descaling the evaporator, sanitizing the water path, scrubbing the bin, baffle, and drop zone, and putting everything back so it’s clean to sight and touch.

While we’re in there, we look at ice production, cube quality, filters, and condenser cleanliness. The goal is to catch “this is slowing down” before it turns into “we ran out of ice at 7 p.m. on Friday.”

After each visit, you get a simple record of what was done and when. You can keep it in your inspection binder so, if someone asks, you’re not guessing—you’ve got proof on paper.

We’re not there to replace your staff. We’re there to take the heavy, technical, time-consuming work off their shoulders so they can focus on food and service while we keep the cube clean and the machine healthy.

Use this the week you know an inspection is coming (or once a month as a routine).

☐ Open the bin lid.

☐ Inspect bin walls, corners, and floor.

☐ Check the underside of the lid and any baffles.

☐ Look for slime, dark spots, mold, or flaky buildup.

If you see any, schedule a deeper clean (not just a quick wipe).

☐ Verify the scoop is not sitting in the ice.

☐ Make sure it’s not tossed on top of glass racks or dirty surfaces.

☐ Confirm the scoop is stored handle up in a clean holder, away from contamination.

☐ Look under and around the machine for standing water.

☐ Check for leaks, damp spots, or musty smells.

☐ Inspect nearby walls and floors for mold, staining, or slime.

☐ Confirm you can show when the last deep clean happened.

☐ If you use a service company, place the most recent work orders or invoices in an easy-to-find folder.

☐ If staff do part of the cleaning, keep a simple log with dates and initials.

☐ Ask at least one person on each shift: “How often is this ice machine cleaned?”

☐ Make sure they can answer calmly and honestly, based on your actual schedule.

☐ Review where logs and records are kept so they can show them if asked.

How often do inspectors expect my restaurant ice machine to be cleaned?

They don’t usually throw out an exact number. What they want to see is that the machine is clean to sight and touch and that you’re following the manufacturer’s recommended schedule or better. In Greenville’s climate, that usually translates to a professional-level clean every 3–6 months, with staff doing lighter cleaning in between.

Can I just use bleach or vinegar to clean my ice machine?

I wouldn’t. Bleach or vinegar in the wrong concentration, on the wrong materials, can damage parts, ruin seals, or still leave biofilm behind. Your safest choice is always manufacturer-approved cleaners and sanitizers designed for ice machines and food-contact surfaces.

Why does my ice machine get slimy so fast around here?

Our combination of warm kitchens, long summers, and high humidity is perfect for biofilm. Every time the bin lid opens, you add a little more warm, moist air and organic material into the mix. Without regular cleaning and good airflow, slime shows up faster here than it would in a drier climate.

Does buying an ice machine from a local company help?

It can. When you work with a local team that installs, maintains, and repairs ice machines, you get equipment matched to your volume, your water, and your layout. You also get people close by who understand Greenville’s climate and inspection expectations, and who can help you keep things on track over time instead of just dropping off a machine and disappearing.

If you open the bin and your first thought is “I don’t want to touch that,” it’s probably time to bring in help. Same thing if you’ve already been written up for the machine, or if ice production keeps dropping and nobody knows why.

local tech will:

At Appliance GrandMasters, we do this work every week for restaurants, bars, coffee shops, and venues all over Greenville and the surrounding Upstate. Our goal is simple: keep your “clean cube” clean, keep your equipment alive longer, and make health inspections one less thing you lose sleep over.

Don’t stress. Appliance GrandMasters provides professional appliance installation and repair services to keep your appliances in top condition. Let our skilled technicians handle the work, ensuring your appliances run smoothly and efficiently. Contact us today for all your appliance repair needs in Greenville.

Get professional home appliance Repairs, maintenance & Installation now!

No worries! We’ve got you covered.

At Appliance GrandMasters, we’ve got your back. Let the experts handle it, so you can enjoy the convenience of smoothly running appliances without the DIY stress.

Our Appliance Repair & Maintenance Service Area

Greenville, Greer, Taylors, Simsponville, Mauldin, Easley, Pickes, Liberty, Pelzer, Williamston, Spartanburg, Honea Path, Belton, Piedmont, Travelers Rest, Wellford, Fountain Inn, Moore, Reidville, Duncan, Lyman, Boiling Springs, Inman, Campobello, Landrum

Formerly known as Mr. Rogers Appliances, we rebranded our appliance repair company to Appliance GrandMasters in June 2020. Since then, we have focused on developing our brand to be customer-oriented.

Fixing appliances has become a passion for us. We enjoy challenges, and we are always preparing and updating ourselves to become the very best.

We accomplish swift and top-notch service by employing efficient and friendly customer service procedures that guarantee accurate answers and solutions.

Our approach involves the careful selection and comprehensive training for the necessary skills to fulfill our customers’ needs. Through these strategies, we strive to consistently provide exceptional service.