Why won’t my dryer stop spinning even when the timer says “Off”?

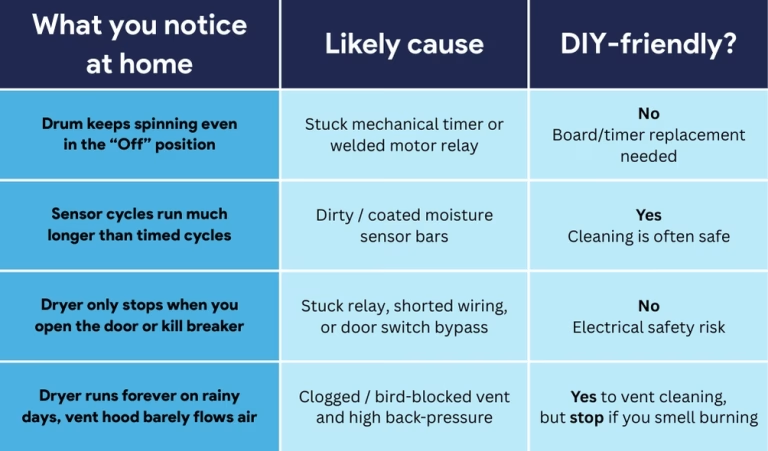

Most of the time it’s either a stuck mechanical timer or a welded motor relay on the control board. The timer or relay is still feeding power to the motor even though the knob or display says the cycle is done. That’s not something you can normally fix with a button press. It usually needs a proper diagnosis and part replacement.

Is it safe to leave a dryer running if it never stops on its own?

I would not treat that as safe. A dryer that refuses to shut off is telling you something in its control or safety circuit isn’t doing its job. The longer it runs, the more heat and wear you’re stacking up on the motor, heater, wiring, and vent. In a humid place like Greenville, where vents already work harder, that’s just asking for trouble. Until it’s checked, unplug it or flip the breaker when you’re not actively using it.

Can I fix a stuck dryer timer or bad relay myself?

Swapping parts inside the console looks simple online, but you’re still dealing with live 240V circuits, wiring harnesses, and boards that can be ruined by one wrong move. If you don’t already own and know how to use a multimeter, this is not the project to learn on. Most Greenville homeowners are better off letting a tech test the timer or board and replace it safely.

Can a clogged vent really make my dryer run too long?

Yes, absolutely. A restricted vent means hot, wet air can’t escape like it should. The dryer keeps sensing “still damp,” especially on Sensor Dry cycles, so it just keeps tumbling. Around Greenville, bird nests, long vent runs, and lint “sludge” from our humid air are a big part of why dryers seem to run forever. Cleaning the vent can fix both drying time and safety at the same time.

How do I know if it’s a sensor issue or a control problem?

Here’s a simple way to feel it out at home: if Sensor Dry runs way too long but a Timed Dry setting behaves normally, that points more toward dirty or coated moisture sensor bars. Cleaning those bars with a little rubbing alcohol often helps. If the dryer ignores both the timer and sensor settings, runs past “Off,” or starts spinning the moment you power it up, that’s more likely a timer, relay, or board issue.

When should I just replace the dryer instead of repairing it?

If the dryer is older, has multiple problems (like control issues plus bad heat or noise), or the repair estimate starts creeping over half the cost of a decent replacement, it’s worth talking about a new unit. For newer dryers in Greenville that only have one clear problem—like a bad board, timer, or relay—repair often makes more sense, especially if the rest of the machine is in good shape and the venting is corrected at the same time.